CE ISO 40Ton Overhead Crane Double Girder for Sale Good Price

40 ton overhead cranes for sale,with CE, ISO certifications, competitive pricing & reliable performance from a trusted Chinese manufacturer.Get your price.

Category: 40 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

CE ISO 40Ton Overhead Crane Double Girder for Sale Good Price

40 ton overhead cranes for sale,with CE, ISO certifications, competitive pricing & reliable performance from a trusted Chinese manufacturer.Get your price.

40 Ton Overhead Crane for Sale

Choosing the right 40 Ton overhead crane depends on your specific operational needs and environment. Below, we highlight the key differences between the popular models to help you make a more informed decision.

QD Standard Double Girder Overhead Crane

The QD model is the industry standard for heavy-duty applications. Its robust double girder design offers high stability, strength, and reliability, making it ideal for lifting large, heavy loads regularly.

Ideal for: Steel mills, heavy manufacturing, construction

Main benefits: High lifting capacity, durability, long service life

QDX European Style, Energy-Efficient Overhead Crane

The QDX model combines a lightweight, energy-efficient design with intelligent features, offering a smart and sustainable solution for a variety of applications.

Ideal for: Manufacturing plants, warehouses, where efficiency is key

Main benefits: Energy savings, intelligent controls, compact structure

LH Single Trolley, Cost-Effective for Medium-Duty Overhead Crane

The LH model is designed for medium-duty applications, providing a cost-effective solution for lifting lighter loads. Its single trolley design is simpler and more affordable than other options.

Ideal for: Light to medium-duty lifting, smaller workshops, warehouses

Main benefits: Lower cost, simple design, easy maintenance

NLH European-Style Hoist, Energy-Saving Design Overhead Crane

The NLH model features a European-style hoist, which helps reduce wear and increases energy efficiency. This model is perfect for continuous use in demanding environments.

Ideal for: Continuous operation in logistics, manufacturing

Main benefits: Energy savings, reduced wear, minimal maintenance

Choosing the Best Model for Your Needs

When selecting the right crane, consider the following:

Workload:

- For heavy-duty lifting, the QD model is the best choice.

- For energy efficiency and lighter designs, the QDX or NLH are better suited.

- If you need a budget-friendly option for light to medium-duty tasks, the LH model works well.

Environment:

- For harsh environments or energy-saving needs, models like QDX and NLH excel.

- For smaller spaces or less demanding tasks, the LH model offers simplicity and cost savings.

ROI (Return on Investment):

- Models with energy-efficient features, like QDX and NLH, may cost more upfront but offer long-term savings on energy and maintenance.

- The LH model offers a lower initial cost, making it a good option if your focus is on minimizing expenses.

Selecting the best crane model is a balance of your operational demands, the environment in which it will operate, and your investment goals. By considering these factors, you can choose the most efficient crane for your business.

Hoisting System Options for 40 Ton Overhead Cranes: Tailored Lifting Mechanisms for Your Operations

The hoisting system is the heart of any overhead crane, determining how efficiently and safely loads are lifted. Choosing the right hoisting mechanism is critical to match your specific operational needs.

Key Hoisting Mechanisms for 40 Ton Overhead Cranes

Electric Hoist Trolley

The electric hoist trolley is the most common and cost-efficient option for most applications. It provides reliable, smooth lifting with low maintenance requirements.

Ideal for: General lifting operations, medium-duty tasks, and routine lifting jobs.

Benefits: Low cost, simple operation, reliable performance.

An open trolley design provides enhanced durability and accessibility for maintenance. This option is ideal for heavy-duty use, where performance and longevity are critical.

Ideal for: Heavy-duty industrial operations with high-frequency lifting.

Benefits: Increased durability, easy to maintain, suitable for demanding environments.

The double hook hoist trolley is designed for handling long, wide, or irregular loads that require lifting from two separate points. This ensures stability and balance while lifting oversized items.

Ideal for: Steel plates, long beams, and other oversized loads.

Benefits: Stability for long loads, improved safety for unbalanced lifting.

The dual or triple trolley system allows for multiple trolleys working together, offering flexibility for handling extremely large, unbalanced, or irregularly shaped loads. This system provides greater lifting flexibility.

Ideal for: Lifting heavy, oversized, or unbalanced loads requiring multiple lifting points.

Benefits: Flexible lifting, ideal for large or uniquely shaped loads.

A rotary trolley is an advanced solution that allows for multi-angle positioning of loads during lifting. This system is perfect for operations that require precise load movement and positioning.

Ideal for: Multi-directional lifting and rotating heavy or delicate loads.

Benefits: Enhanced precision, allows for rotation during lifting, great for complex handling tasks.

How to Match the Hoisting System to Your Operations

Choosing the right hoisting system depends on the type of loads you handle and your operational requirements:

- For general use: The electric hoist trolley is often sufficient for most industries, offering cost-efficiency and reliability.

- For heavy-duty operations: If you need a more durable system, the open trolley design provides extra strength and easier maintenance.

- For long or oversized loads: The double hook hoist trolley is ideal for ensuring stability and balance while lifting large materials.

- For large, unbalanced loads: The dual or triple trolley system offers flexible and powerful lifting capabilities, especially for complex, heavy, or irregular loads.

- For precision lifting and rotation: The rotary trolley system allows for advanced control and precision, perfect for tasks requiring multi-angle positioning.

Each hoisting system has distinct advantages based on the operational needs of your business. Choosing the right system will ensure optimal efficiency, safety, and cost-effectiveness in your crane operations.

Crane Control Options: Enhance Safety & Efficiency

The crane control system is essential for safe, smooth, and efficient crane operation. Selecting the right control system can make a significant difference in both safety and productivity.

Pendant Control: The pendant control is a wired, manual control system, commonly used for its simplicity and reliability. It provides operators with full control over crane movements while keeping them safely away from the load.

Ideal for: Small to medium-sized operations where basic control is sufficient.

Benefits: Reliable, straightforward operation, cost-effective, enhances safety by keeping operators at a distance.

Remote Control: The remote control system uses wireless technology to allow operators to control the crane from a distance, offering more flexibility and improved safety. It enables the operator to stay clear of hazards while maintaining control over the crane.

Ideal for: Larger operations or those where the operator needs to move freely around the workspace.

Benefits: Greater flexibility, reduces operator exposure to potential dangers, and improves overall safety.

PLC Control; PLC (Programmable Logic Controller) control brings automation to crane operations, providing more precision and efficiency. It allows for more complex tasks and is ideal for cranes involved in high-precision lifting or repetitive operations.

Ideal for: High-precision tasks or environments where consistency is key, such as manufacturing plants.

Benefits: Increased operational efficiency, higher precision, better monitoring of operations.

Automated System: A automated system takes automation to the next level, reducing manual intervention and allowing the crane to perform tasks without constant input from the operator. This system is used for highly repetitive tasks where speed and accuracy are critical.

Ideal for: Precision and high-volume operations where minimal human involvement is required.

Benefits: Increased productivity, reduced errors, and enhanced safety due to minimal operator intervention.

Choosing the Right Control System

When selecting a crane control system, it's important to consider both safety and efficiency:

- For simplicity and reliability: Choose the pendant control for smaller operations or where basic control is sufficient.

- For greater flexibility and safety: The remote control system is ideal if your operators need to move freely or need to stay out of hazardous zones.

- For precision and automation: If you require high-precision lifting, the PLC control system is perfect for more complex tasks.

- For high-volume and repetitive tasks: A fully automated system reduces manual effort, improves accuracy, and is ideal for large-scale operations requiring speed and consistency.

By selecting the appropriate control system, you can not only enhance safety but also improve the operational efficiency of your overhead crane.

Custom Design Options: Adapting to Specialized Work Environments

Each work environment comes with its unique set of challenges, and having a custom-designed 40 Ton overhead crane can make a significant difference in performance, safety, and longevity. Whether you're dealing with limited space, harsh chemicals, extreme temperatures, or dust and corrosion, the right design options will ensure your crane performs optimally in your specific environment.

- Low Headroom Design For space-restricted workshops.

- Explosion-Proof Design Essential for chemical plants and hazardous zones.

- Anti-Corrosion & Anti-Dust Designs Protecting cranes in harsh environments.

- Sanitary & High-Temperature Resistant Designs Meeting industry-specific needs.

Low Headroom Design: For workshops with limited vertical space, a low headroom design is essential. This design allows you to maximize lifting height while minimizing the crane'soverall height, making it an ideal choice for buildings with lower ceilings.

Ideal for: Workshops, factories, or warehouses with height limitations.

Benefits: Increased lifting capacity within space-restricted environments, optimized space utilization.

Explosion-Proof Design: In industries such as chemical plants, oil refineries, or areas with potentially explosive atmospheres, an explosion-proof design is crucial. These cranes are equipped with special enclosures and safety features to prevent sparks or heat buildup, ensuring safety in hazardous zones.

Ideal for: Chemical plants, refineries, and other explosive environments.

Benefits: Meets strict safety standards, reduces the risk of fire or explosions, ensures compliance with industry regulations.

Anti-Corrosion & Anti-Dust Designs: If your crane will be exposed to harsh, corrosive environments (such as coastal areas or chemical facilities), anti-corrosion and anti-dust designs are essential. These cranes are treated with specialized coatings or built with materials resistant to rust and dust accumulation.

Ideal for: Coastal environments, mines, cement plants, or any harsh environment.

Benefits: Extended crane lifespan, minimal maintenance needs, better performance in dusty or corrosive conditions.

Sanitary & High-Temperature Resistant Designs: For industries such as food processing, pharmaceuticals, and steel mills, having cranes that meet sanitary standards and can withstand high temperatures is crucial. These cranes are designed with materials that resist extreme heat, are easy to clean, and can handle high-temperature environments.

Ideal for: Food processing plants, steel mills, foundries, and high-temperature areas.

Benefits: Complies with sanitation standards, maintains performance in high-heat environments, reduces downtime due to extreme conditions.

Buyer'sCustomization Checklist

When selecting a custom-designed crane, keep the following points in mind:

- Space Constraints: Choose a design that maximizes lifting height within the available space (e.g., low headroom).

- Environmental Conditions: Make sure the crane is equipped for the specific environmental challenges, such as anti-corrosion or explosion-proof features.

- Safety Compliance: Verify that the design meets safety standards, including fire prevention, electrical safety, and environmental protection.

- Operational Efficiency: Consider how customization can enhance crane performance and efficiency in your unique work environment.

- Longevity: Look for design features that improve the crane'slifespan in your specific setting, like corrosion-resistant materials or high-temperature resistance.

By choosing the right custom design options, you ensure your 40 Ton overhead crane performs optimally and safely, no matter the challenges your work environment presents.

Below-the-Hook Attachments: Maximize Load Handling Efficiency

Selecting the right attachment for your 40 Ton overhead crane is crucial to ensuring that it operates efficiently and safely while handling different types of loads. Below-the-hook attachments are designed to fit your crane and allow it to perform a range of specialized tasks, whether it'slifting bulk materials, delicate items, or heavy metal. The right choice can enhance performance, increase safety, and reduce operational costs.

- Standard Hook General-purpose lifting.

- Grab Bucket Ideal for bulk materials.

- Electromagnetic Lifter For steel plates, billets, and scrap metal.

- Vacuum Lifter For lifting glass, metal sheets, and delicate materials.

- Beam Spreaders (Standard, Electric, Container) For efficient long load handling.

Standard Hook: The standard hook is the most versatile lifting tool for general lifting. It is ideal for a wide range of materials, including machinery, equipment, and most standard industrial loads.

Ideal for: General-purpose lifting, everyday tasks in workshops, factories, and warehouses.

Benefits: Simple to use, cost-effective, and widely available.

Grab Bucket: A grab bucket is designed for bulk materials, such as sand, gravel, scrap metal, and other loose or granular substances. The bucket grabs and holds large amounts of material, making it easier to move large loads quickly.

Ideal for: Cement plants, mining operations, and material handling yards.

Benefits: Handles large volumes of bulk material efficiently, reduces handling time.

Electromagnetic Lifter; Electromagnetic lifters are perfect for lifting steel plates, billets, scrap metal, and other ferrous materials. The electromagnet is powered by electricity and can easily lift and move heavy metallic materials.

Ideal for: Steel mills, metal fabrication shops, and scrap yards.

Benefits: Safe and secure lifting of heavy metallic loads, minimizes the risk of damage during lifting.

Vacuum Lifter: A vacuum lifter uses suction to handle delicate or non-ferrous materials, such as glass panels, metal sheets, and other flat or sensitive items. This tool is especially helpful when precision is required, and the material cannot be damaged.

Ideal for: Glass manufacturing, metal sheet handling, and other industries requiring careful lifting of delicate materials.

Benefits: Handles fragile materials safely, prevents damage, and ensures precise handling.

Beam Spreaders (Standard, Electric, Container); Beam spreaders are designed to handle long loads such as pipes, beams, and large pieces of equipment. Whether manual or electric, they provide a means to spread the load evenly and ensure safe, stable lifting.

Ideal for: Construction sites, heavy manufacturing, and port operations.

Benefits: Increases stability for long, flexible materials, improves lifting efficiency and safety.

Attachment Selection: How to Choose the Best Lifting Tool for Your Needs

When selecting a below-the-hook attachment, consider the following factors to maximize both efficiency and cost-effectiveness:

- Material Type: Choose an attachment that suits the specific material you'll be lifting (e.g., use a vacuum lifter for glass, an electromagnetic lifter for steel).

- Load Characteristics: Ensure the attachment is designed to handle the size and weight of the materials you're lifting.

- Efficiency Needs: Some attachments, like beam spreaders, are designed for fast and efficient handling of long loads, reducing lifting times.

- Safety and Stability: Attachments such as the grab bucket and electromagnetic lifter improve safety by securing the load during handling, minimizing the risk of accidents.

- Maintenance: Some attachments require more maintenance than others. Choose based on your operational capacity to manage and maintain them.

By selecting the right below-the-hook attachment, you can ensure that your 40 Ton overhead crane performs at its best, improving both operational efficiency and safety. The right choice will help you handle a wide range of materials, keeping costs low and productivity high.

Safety Features: Ensuring the Protection of Operators & Cranes

Safety is paramount when operating a 40 Ton overhead crane. Whether its protecting the operators or the crane, integrating safety features can significantly reduce risks and prevent costly accidents. Below are key safety features that should be considered when choosing your crane.

- Overload Protection Prevents unsafe lifting conditions.

- Emergency Stop & Collision Avoidance Enhances safety during crane operations.

- Anti-Sway Technology Reduces load swing for precision handling.

- Dual Brake Systems Critical for steel mills and ladle cranes.

Overload Protection; Overload protection ensures that the crane does not lift beyond its capacity, preventing dangerous situations where the crane could tip, damage the load, or break down. This safety feature automatically cuts off power or triggers alarms when the load exceeds safe limits.

Benefits: Protects both the crane and operators from accidental overloading, preventing costly repairs and ensuring safe operations.

Emergency Stop & Collision Avoidance: An emergency stop system allows operators to stop crane operation immediately in case of an emergency. Coupled with collision avoidance technology, it reduces the risk of the crane colliding with structures, equipment, or personnel.

Benefits: Increases safety by allowing quick response to emergencies, reducing damage and injury risks.

Anti-Sway Technology; Anti-sway technology stabilizes the load and reduces its swinging during transportation. This is particularly important when handling large, heavy, or unbalanced loads that can cause instability.

Benefits: Provides smoother, more controlled lifting, enhances precision, and improves operator confidence during handling.

Dual Brake Systems; Dual brake systems are essential for cranes operating in high-risk environments such as steel mills. These systems ensure that even if one brake fails, the other can safely stop the crane, reducing the risk of accidents when handling extremely heavy loads like molten metal.

Benefits: Provides an additional layer of safety in high-stress environments, minimizing the chances of a catastrophic failure.

Compliance: Meeting Global Safety Standards

Ensuring that your 40 Ton overhead crane meets global safety standards is crucial for both operational success and legal compliance. Look for cranes that are certified with recognized safety standards such as:

- ISO (International Organization for Standardization) Sets global standards for safety and quality.

- CE Ensures the crane meets European Union health, safety, and environmental protection requirements.

- OSHA (Occupational Safety and Health Administration) Ensures the crane complies with safety regulations in the United States.

By adhering to these standards, your crane will not only operate safely but also meet the legal and regulatory requirements, ensuring long-term protection for both personnel and equipment.

Why Safety Features Matter

Incorporating the right safety features ensures that your 40 Ton overhead crane provides a secure working environment for operators and minimizes the risk of costly downtime and repairs. With the right safety measures in place, you can improve productivity while adhering to industry safety standards. This is essential for any heavy-duty operation, whether in manufacturing, construction, steel mills, or shipping industries.

Pricing Guide: Costs of a 40 Ton Overhead Crane

When purchasing a 40 Ton overhead crane, it'simportant to have a clear understanding of the factors that influence pricing. By breaking down these cost components, you can ensure you are making an informed decision and getting the best value for your investment.

Key Cost Factors

Design Complexity: The design complexity is one of the biggest factors that affect crane pricing.

- Standard Configuration: A basic, top-running double girder crane typically costs less, as it has a more traditional design with fewer customizations.

- Custom Configuration: Custom designs such as specific load capacities, span requirements, or specialized structures an raise the price. The more customized the crane, the more expensive it tends to be due to additional engineering and manufacturing requirements.

Tip: If your operation has unique space or load requirements, opting for a custom design may be necessary, but it will add to the overall cost.

Hoisting System & Control Upgrades: The type of hoisting system and control features you choose will impact the final price.

- Standard Hoisting Systems: Basic electric hoist trolleys are cost-effective for most operations.

- Advanced Hoisting Systems: Options like open trolleys, rotary trolleys, or dual/tandem hoisting systems can add significant costs due to their specialized features.

- Control Upgrades: The level of automation and control also affects pricing. A pendant control system is typically the most affordable, while PLC controls or fully automated systems offer more precision and automation but come at a higher price.

Tip: Choosing advanced control systems can improve efficiency and reduce labor costs, but you should weigh this against the additional upfront investment.

Environmental Adaptations: Cranes designed for harsh environments require more specialized components, which can increase costs.

- Explosion-Proof Design: Critical for hazardous industries like chemical plants or refineries.

- Anti-Corrosion & Anti-Dust Designs: Ideal for coastal areas, foundries, or industries like mining and cement production. These adaptations use high-quality materials to withstand extreme conditions, adding to the overall cost.

- High-Temperature Resistant Design: Essential for environments like steel mills or foundries that deal with extreme heat.

Tip: If your crane will operate in a challenging environment, it'simportant to invest in the necessary adaptations to ensure long-term durability, even though this will increase costs.

Installation & After-Sales Support: The installation process and ongoing after-sales support are crucial parts of your total investment.

- On-Site Setup: Depending on your location, installation services may include training, system integration, and commissioning, all of which will add to the price.

- Maintenance & Support: Ongoing support like regular maintenance, spare parts, and service contracts are essential for keeping your crane running smoothly over the years.

Tip: When evaluating suppliers, it'simportant to consider the long-term costs associated with installation, maintenance, and after-sales services.

Estimated Price Range for a 40 Ton Overhead Crane

Standard 40 Ton Overhead Crane

- Price Range: $30,000 $75,000

- Includes: Basic double-girder design, standard hoisting system, and simple controls.

- Best for: General lifting applications in steel mills, manufacturing, and warehouses.

Customized 40 Ton Overhead Crane

- Price Range: $80,000 $150,000

- Includes: Special lifting mechanisms, custom spans, anti-sway systems, and environmental protection features (e.g., explosion-proof, anti-corrosion).

- Best for: Heavy-duty operations with specific safety or performance requirements.

Full-Package 40 Ton Overhead Crane with Runway System

- Price Range: $150,000 $250,000+

- Includes: Crane + runway beams and columns, full installation support.

- Best for: Facilities without existing runway systems or leased workshops needing a complete lifting solution.

Price Breakdown for Overhead Cranes by Capacity (For Reference)

| Crane Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Estimated Price (USD) |

|---|---|---|---|---|

| 5 Ton | 7.5 31.5 | 6 30 | 220-480V/3P/50Hz | $5,800 $72,000 |

| 10 Ton | 7.5 31.5 | 6 30 | 220-480V/3P/50Hz | $6,500 $79,000 |

| 16 Ton | 7.5 31.5 | 6 30 | 220-480V/3P/50Hz | $7,800 $86,000 |

| 20 Ton | 7.5 31.5 | 6 30 | 220-480V/3P/50Hz | $8,600 $95,000 |

| 25 Ton | 7.5 31.5 | 6 30 | 220-480V/3P/50Hz | $9,800 $110,000 |

| 40 Ton | 7.5 31.5 | 6 30 | 220-480V/3P/50Hz | $30,000 $250,000+ |

Note: Prices vary based on crane configuration, shipping location, and customization needs. Contact us for an accurate quote based on your requirements.

Cost-Effective Purchase Options: Standard Crane vs. Crane Kit vs. Full-Package with Runway System

When purchasing a 40 Ton overhead crane, buyers must decide between a full-package solution or a more economical crane kit. The right choice depends on your existing infrastructure, budget, and installation needs. Below is a breakdown of each option and its benefits.

Standard Overhead Crane: Mounted on Existing Structures

A standard overhead crane is designed to be installed on pre-existing workshop structures or within a newly constructed facility. It includes essential crane components but does not come with a runway system.

Best for buyers who already have a support structure in place.

- Cost-effective: No need for additional steelwork.

- Suitable for workshops with integrated support beams or crane-ready buildings.

- Not suitable for workshops without a supporting structure.

Who should choose this?

If your facility has a built-in runway system, this option minimizes costs while providing a fully functional lifting system.

Cost-Saving Option: Overhead Crane Kit Without Main Girder

An overhead crane kit includes all essential lifting components but excludes the main girder, which the buyer can source or fabricate locally.

What's Included?

- Electric hoist or trolley system

- End trucks and wheels

- Crane control system (remote, pendant, or PLC)

- Electrical components and accessories

Advantages of a Crane Kit:

- Lower material costs: Fabricating the girder locally reduces overall expenses.

- Reduced transportation costs: Avoids shipping bulky steel girders internationally.

- Custom girder design: Offers flexibility in material selection and fabrication.

Drawbacks:

- Requires the buyer to manufacture or source the girder, which might not be practical for all companies.

Who should choose this?

This option is ideal for buyers who want to save on costs and have access to local steel fabrication.

Full-Package Option: Overhead Crane with Runway System

For workshops without a supporting structure—such as leased spaces or new facilities—a full-package overhead crane with a runway system is the most practical choice.

What's Included?

- Complete 40 Ton overhead crane system

- Steel runway beams and columns (customized to your workshop layout)

- Installation support and technical guidance

Advantages of a Full-Package Solution:

- Turnkey solution: No need for additional structural work.

- Ideal for leased workshops where modifications are limited.

- Engineered for stability and efficiency, ensuring long-term reliability.

Drawbacks:

- Higher initial investment compared to standard cranes or kits.

Who should choose this?

If your site lacks a runway system, this all-in-one package offers a seamless installation and ensures full structural compatibility.

This revision improves readability and corrects some wording and formatting errors for a more professional presentation.

Which Option Is Best for You?

| Purchase Option | Best For | Pros | Cons |

|---|---|---|---|

| Standard Overhead Crane (Without Runway System) | Facilities with existing structures | Lower cost, easy integration | Not suitable for workshops without support beams |

| Overhead Crane Kit (Without Main Girder) | Buyers looking for cost savings by sourcing the girder locally | Reduced material & shipping costs, more flexibility | Requires fabrication of the girder |

| Full-Package Crane with Runway System | New workshops or leased facilities without existing support | Complete, custom-fit solution | Higher upfront cost |

Final Thoughts

Selecting the right 40 Ton overhead crane solution depends on your facility layout, budget, and long-term operational needs.

- If you have an existing structure, a standard crane is the most economical.

- If you want to save on material and transport costs, a crane kit is the best value.

- If your facility lacks a support system, a full-package crane with a runway system is the most practical.

By choosing the right option, you can optimize costs, streamline installation, and maximize your investment in heavy-duty lifting equipment.

How to Get the Best Price?

Specify Your Needs Clearly Define lifting height, span, working environment, and additional features to get an accurate quote.

Compare Crane Kits vs. Full Systems If you have an existing structure, a crane kit (without a main girder) can reduce costs.

Consider Local Fabrication for Large Components Sourcing the main girder locally can lower transportation costs.

Choose a Reliable Overhead Supplier Buying directly from a manufacturer with CE & ISO certifications ensures cost savings and quality assurance.

For a customized quote, reach out to us with your workshop details and lifting requirements.

Applications of 40 Ton Overhead Cranes: Industries That Benefit Most

A 40 Ton overhead crane is a heavy-duty piece of equipment designed for industries that need to lift and move massive loads with precision and efficiency. Here'sa look at some of the key industries where these cranes provide maximum value:

- Steel Mills & Foundries Handling molten metal, steel coils, and billets.

- Heavy Machinery Manufacturing Lifting large machine components and assemblies.

- Construction & Infrastructure Lifting precast concrete and large structures.

- Shipbuilding & Marine Yards Transporting ship sections and cargo.

- Energy Sector Power plants, wind turbine assembly, and hydro projects.

Steel Mills & Foundries

- Primary Use: Handling molten metal, steel coils, and billets.

- Why 40 Ton Cranes: Steel mills and foundries require cranes that can safely lift heavy, high-temperature materials like molten metal. A 40 Ton crane ensures these materials are moved efficiently while minimizing the risk of accidents.

- Benefits: High lifting capacity, heavy-duty construction, and advanced safety features ensure smooth and safe operations in harsh, high-heat environments.

Heavy Machinery Manufacturing

- Primary Use: Lifting large machine components and assemblies.

- Why 40 Ton Cranes: These cranes are ideal for lifting large, heavy machine parts, such as engines, turbines, and other large machinery used in manufacturing.

- Benefits: The precision and lifting capacity of the 40 Ton crane allow for safe handling of massive components, boosting productivity and reducing manual labor.

Construction & Infrastructure

- Primary Use: Lifting precast concrete elements and large structures.

- Why 40 Ton Cranes: In construction, cranes are crucial for handling heavy building materials like concrete beams, columns, and sections of steel infrastructure. A 40 Ton crane provides the necessary power and stability for these high-weight lifts.

- Benefits: The 40 Ton overhead crane ensures efficient material handling, reducing delays and improving project timelines, especially for large-scale infrastructure projects.

Shipbuilding & Marine Yards

- Primary Use: Transporting ship sections and large cargo.

- Why 40 Ton Cranes: Shipbuilding requires cranes that can lift and move large sections of ships, steel plates, and cargo with precision. A 40 Ton crane offers the lifting capacity needed to transport massive pieces of a ship'shull or large equipment within shipyards.

- Benefits: High lifting capacity and advanced control systems allow for accurate placement of heavy materials, speeding up the shipbuilding process while ensuring safety.

Energy Sector

- Primary Use: Lifting equipment for power plants, wind turbines, and hydroelectric projects.

- Why 40 Ton Cranes: The energy sector requires lifting solutions for heavy equipment such as turbines, generators, and power transmission parts. A 40 Ton crane ensures the safe and efficient handling of these massive loads, particularly in energy production facilities.

- Benefits: Strong load handling capabilities allow for streamlined construction and maintenance of energy infrastructure, from wind turbine assembly to hydropower project installations.

Conclusion

The 40 Ton overhead crane is an essential tool for industries that need to move large, heavy materials in a safe and efficient manner. Whether you're in steel manufacturing, construction, shipbuilding, or energy production, these cranes offer the power, precision, and safety necessary to meet demanding operational requirements.

Why Invest in a 40 Ton Overhead Crane? Advantages for Heavy-Duty Industrial Material Handling

A 40 Ton overhead crane is an essential piece of equipment for heavy-duty material handling in industries like steel mills, construction, and manufacturing. These cranes are designed to lift and move large, heavy loads efficiently. Whether you are moving steel coils, construction materials, or heavy machinery parts, a 40 Ton crane provides the strength and durability needed for the job.

- Powerful lifting capacity: Handles heavy loads with ease.

- Increased productivity: Reduces manual labor and boosts efficiency.

- Versatile applications: Suitable for a range of industries and tasks.

Investing in a high-quality crane ensures that you can handle demanding workloads without compromising on performance.

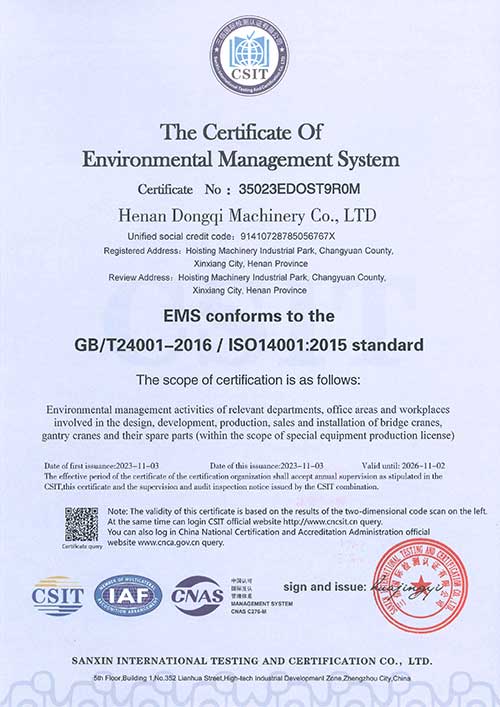

Overhead Cranes: CE, ISO Certifications & 3rd Party Inspection Ensuring Top Quality, Safety, and Compliance

When buying a 40 Ton overhead crane, it's crucial to choose one that meets international safety and quality standards. Cranes that are CE (European Conformity) and ISO certified are a good indicator of high manufacturing standards. These certifications ensure that the crane is built to perform safely and reliably under industrial conditions.

- CE certification: Confirms compliance with European Union safety standards.

- ISO certification: Guarantees consistent quality in design, production, and service.

- Third-party inspections: Provides extra assurance that the crane meets all regulatory and safety requirements.

Choosing a crane with these certifications minimizes the risk of costly downtime and ensures that your operations remain safe.

Standard Design: Top-Running Double Girder Overhead Crane Industry's Preferred Design for 40 Ton Lifting Capacity

The top-running double girder overhead crane is the most commonly used design for handling 40 Ton loads. This design offers excellent stability and is ideal for heavy-duty operations. With two parallel beams (or girders) supporting the load, this crane type is perfect for industries with high operational demands.

- Enhanced stability: Double girder design ensures even load distribution.

- Higher lifting capacity: Suitable for lifting 40 tons and more.

- Durability: Built to withstand harsh working environments.

The top-running double girder crane is trusted across industries for its reliability and ability to lift heavy loads consistently.

Critical Buyer Considerations Space Constraints, Lifting Frequency, Customization Needs, and Cost-Effectiveness

Before purchasing a 40 Ton overhead crane, there are several key factors to consider:

- Space Constraints: Ensure the crane fits within your workshop or warehouse. Consider low headroom or custom designs if your space is limited.

- Lifting Frequency: How often will the crane be in use? High-frequency operations may require a more robust, high-performance crane.

- Customization Needs: Some environments may require special features, like explosion-proof designs or anti-corrosion coatings.

- Cost-Effectiveness: It's important to balance price with quality. A cheaper crane might cut costs upfront but could lead to higher maintenance expenses in the long run.

Taking the time to evaluate these factors will help you choose the right crane for your specific needs.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch